Customized Lockout Boards: Tailored Safety Solutions for Your Workplace

The Importance of Customization

Every industrial setting has its own set of challenges, equipment types, and safety protocols. A generic lockout board may not adequately address the specific requirements of your facility. Customization allows you to design a lockout board that seamlessly integrates with your existing safety infrastructure, making it easier for employees to follow LOTO procedures correctly. Here are some key benefits of choosing a customized lockout board:

1.Tailored to Your Equipment and Processes

2.Enhanced Safety and Compliance

3.Brand Reinforcement

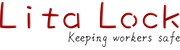

Customization Options

When you choose [Company Name] for your customized lockout board, you have a wide range of options to create a product that is perfect for your workplace.

1.Layout Design

2.Material Selection

3.Content and Labeling

The process of getting a customized lockout board from [Company Name] is simple and straightforward.

1.Consultation

2.Design Approval

3.Production and Delivery

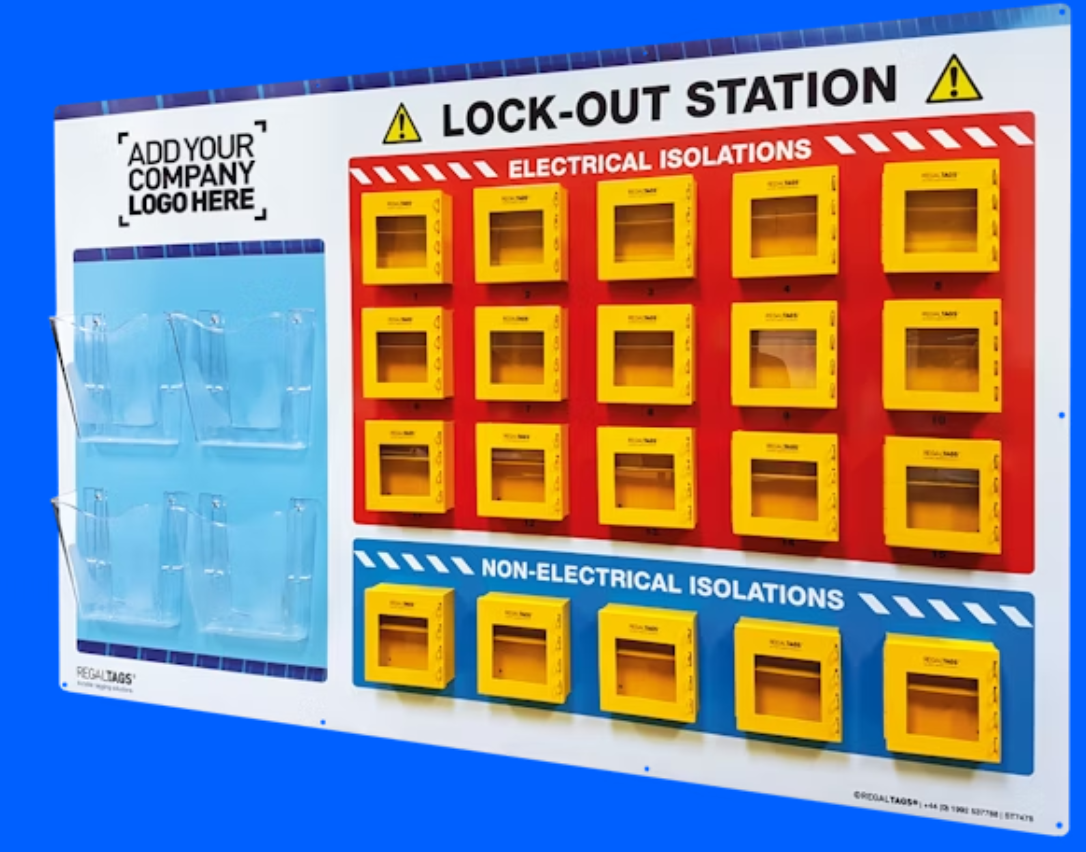

Case Studies

To illustrate the effectiveness of our customized lockout boards, here are a few case studies from our satisfied customers.

Case Study 1: Manufacturing Facility

Challenge: A large manufacturing facility had a complex network of equipment, including heavy machinery, conveyor systems, and electrical panels. Their existing lockout system was disorganized, and employees often had difficulty finding the right lockout devices and following the correct procedures. This led to delays in maintenance operations and increased the risk of accidents.

Solution: We worked with the facility's safety team to design a customized lockout board that was tailored to their specific equipment and processes. The board was divided into sections based on the different areas of the plant, and each section had labeled compartments for the corresponding lockout devices. We also included custom-printed instructions and safety messages in multiple languages to ensure clear communication.

Result: After implementing the customized lockout board, the facility saw a significant improvement in the efficiency of their LOTO procedures. Employees were able to quickly locate the necessary lockout tools and tags, reducing the time it took to complete maintenance tasks. The clear instructions and safety messages also helped to increase compliance with LOTO procedures, resulting in a safer working environment.

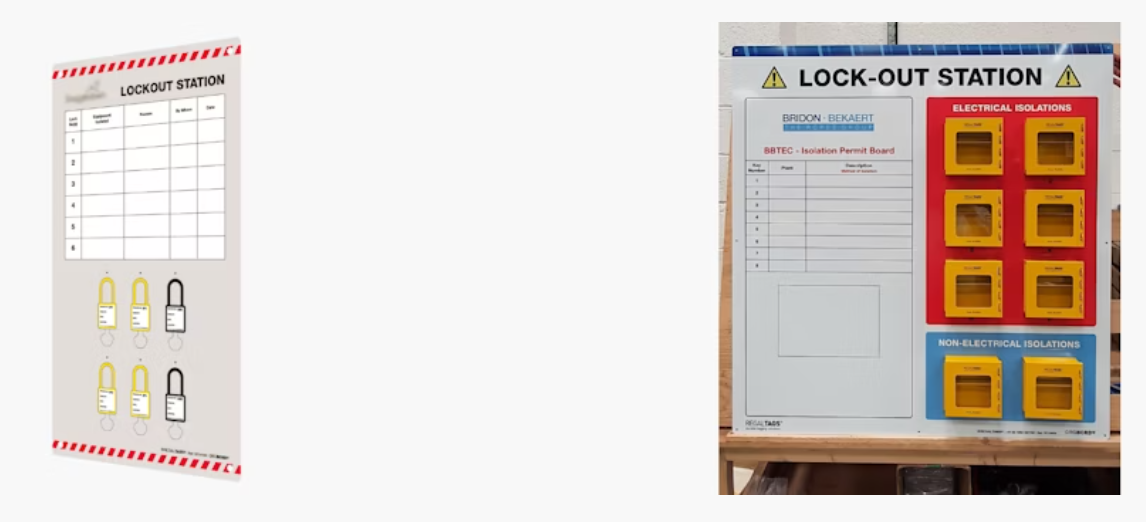

Case Study 2: Power Generation Plant

Challenge: A power generation plant needed to upgrade their lockout system to meet new regulatory requirements. They also wanted to improve the visibility and organization of their lockout equipment to enhance safety and prevent unauthorized access to energized equipment.

Solution: We designed a large, wall-mounted lockout board for the power generation plant that was made of heavy-duty steel for durability. The board was customized with the plant's logo and colors to reinforce their brand identity. It included multiple rows of hooks for hanging padlocks, as well as clear acrylic windows for displaying important documents such as lockout/tagout procedures and inspection records.

Result: The customized lockout board not only met the regulatory requirements but also provided a highly visible and organized solution for the plant's lockout needs. The clear labeling and layout made it easy for employees and contractors to follow the LOTO procedures, reducing the risk of accidents. The board also served as a visual reminder of the importance of safety, helping to create a culture of safety within the plant.

Lita Lock, a China based manufacturer, since 2017, active in manufacturing safety padlocks, electrical lockout, valve lockout, lockout station, tags and other lockout & tagout for global partners.

To help customers compliance with OSHA Standard 29 CFR 1910.147, Lita Lock does not only offer design, production and final assembly, but also a complete lockout & tagout solution for various industries.

Lita Lock pursues the competitiveness on creative, quality control, technology and sustainable development. As the founder of Lita Lock, Iris Chen says: “Many things have changed, but one thing that has not—our original intention to start businesses: keeping workers safe.” Together, we make work environments safer.

Sales Manager: Iris Chen

Email: iris@litalock.com

Whatsapp: + 86 13165872593

#CircuitBreakerLockoutKit #ValveLockoutKit #CableLockoutKit #PlugLockoutKit #PneumaticLockoutKit

#LockoutKit #LockoutTagoutKit #LOTOKit #SafetyLockoutKit #IndustrialLockoutKit #ElectricalLockoutKit #LockoutTagoutEquipment #LOTOSafetyKit #OSHALockoutKit #LockoutKitforManufacturing #LockoutKitforElectricalPanels #LockoutKitforIndustrialMaintenance #BradyLockoutKit #MasterLockLockoutKit #ABUSLockoutKit #HowtoChooseaLockoutKit #CustomizableLockoutKit #Litalock #Customlockoutpanelforelectricalsafety #Customizedlockoutboard #Personalizedlockoutboard #Lockouttagoutboard(LOTOboard) #PersonalizedLOTOboardforworkplacesafety #Customizablelockoutstationformachinery #EngravedlockoutboardforOSHAcompliance #OSHAcompliantlockoutboardforenergycontrol #Lockoutpointidentificationboard #Magneticoradhesivelockoutboard #Modularlockoutboardformultiplepadlocks #Lockoutdeviceorganizationboard